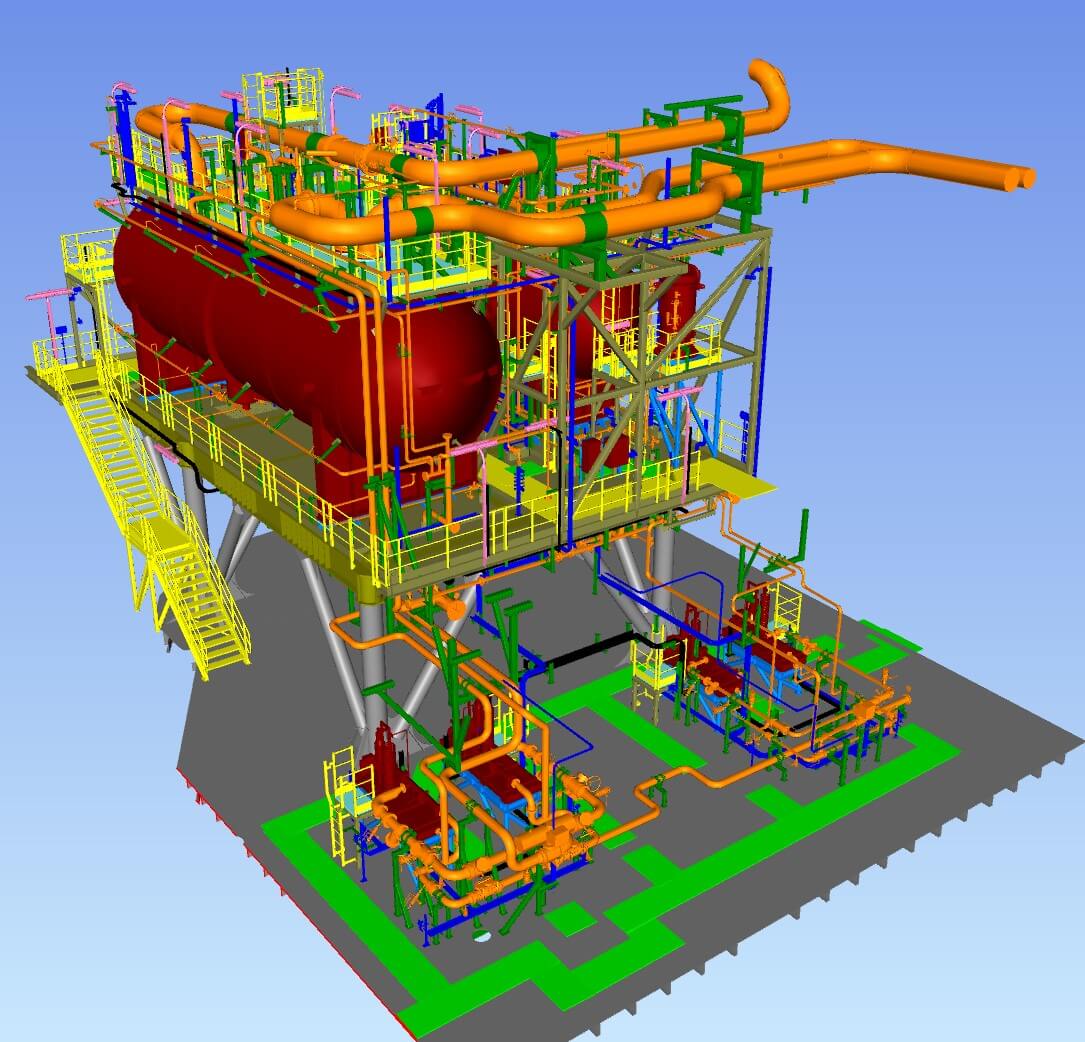

Pipe stress analyses are executed in accordance with recognized design standards, pipe specifications and customer requirements. We use Caesar II software to analyse e.g. design and operating temperatures and pressures, internal/external loads such as slug flow, wind, snow/ice, accelerations, external forces, imposed displacements and accidental cases with blast pressures and/or accidental heeling.

Pipe stress analyses are performed to document compliance with design standards, regulatory codes, customer specifications as well as determining support loads, support locations, equipment nozzle loads, pipe stresses and thermal displacements. We also implement pipe stress analyses/nozzle load analyses of rotation equipment such as pumps and compressors according to recognized standards.

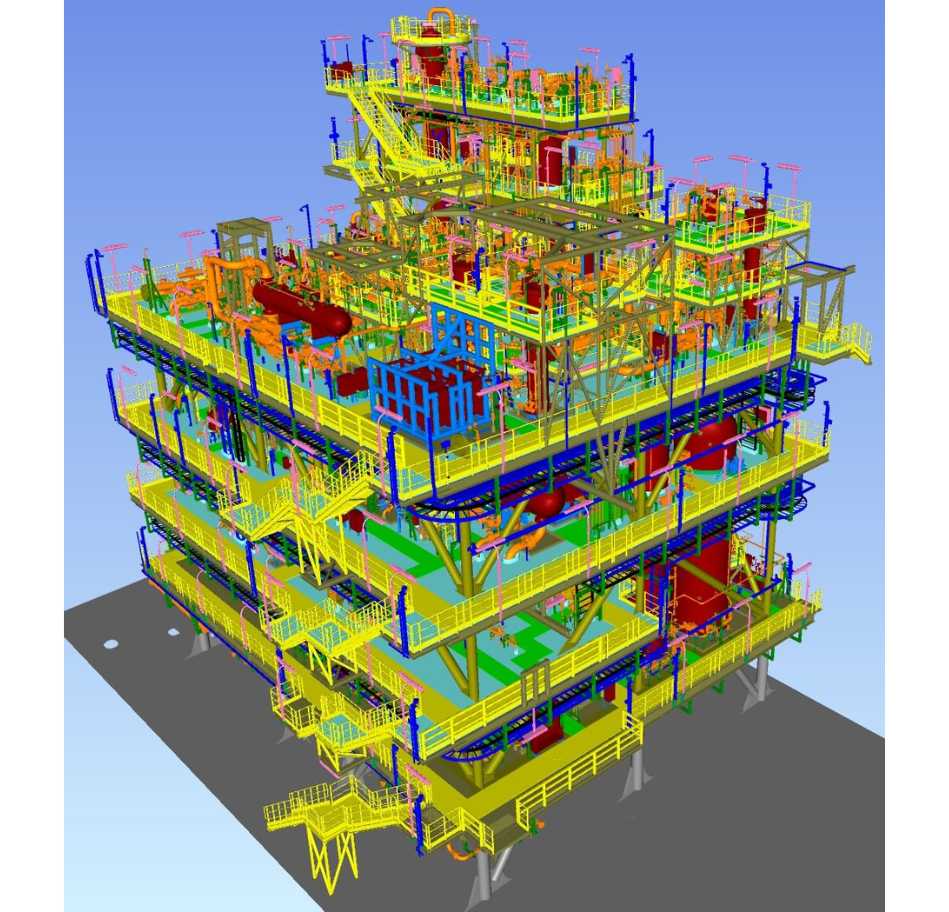

We design

- In-place

- Load-out

- Lifting

- Transport incl. seafastening

- Fatigue

- Explosion

- Vibration/resonance

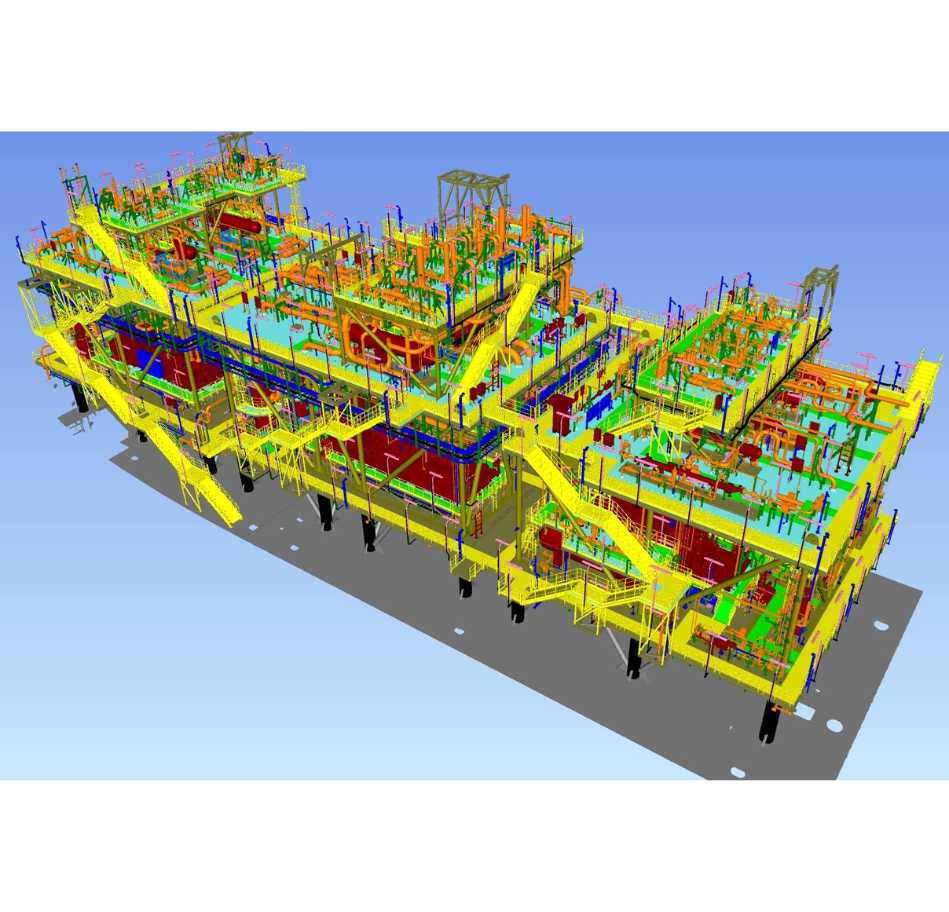

We perform

- Linear-elastic static analyses

- Non-linear analyses

- Material nonlinearities

- Dynamic loading

- Time/history analyses

- Explicit analysis

- Fatigue verification

We use

- DNVGL standards

- ABS standards

- NORSOK standards

- Eurocode standards

- IGC code

- API